Serving tech enthusiasts for over 25 years.

TechSpot means tech analysis and advice you can trust.

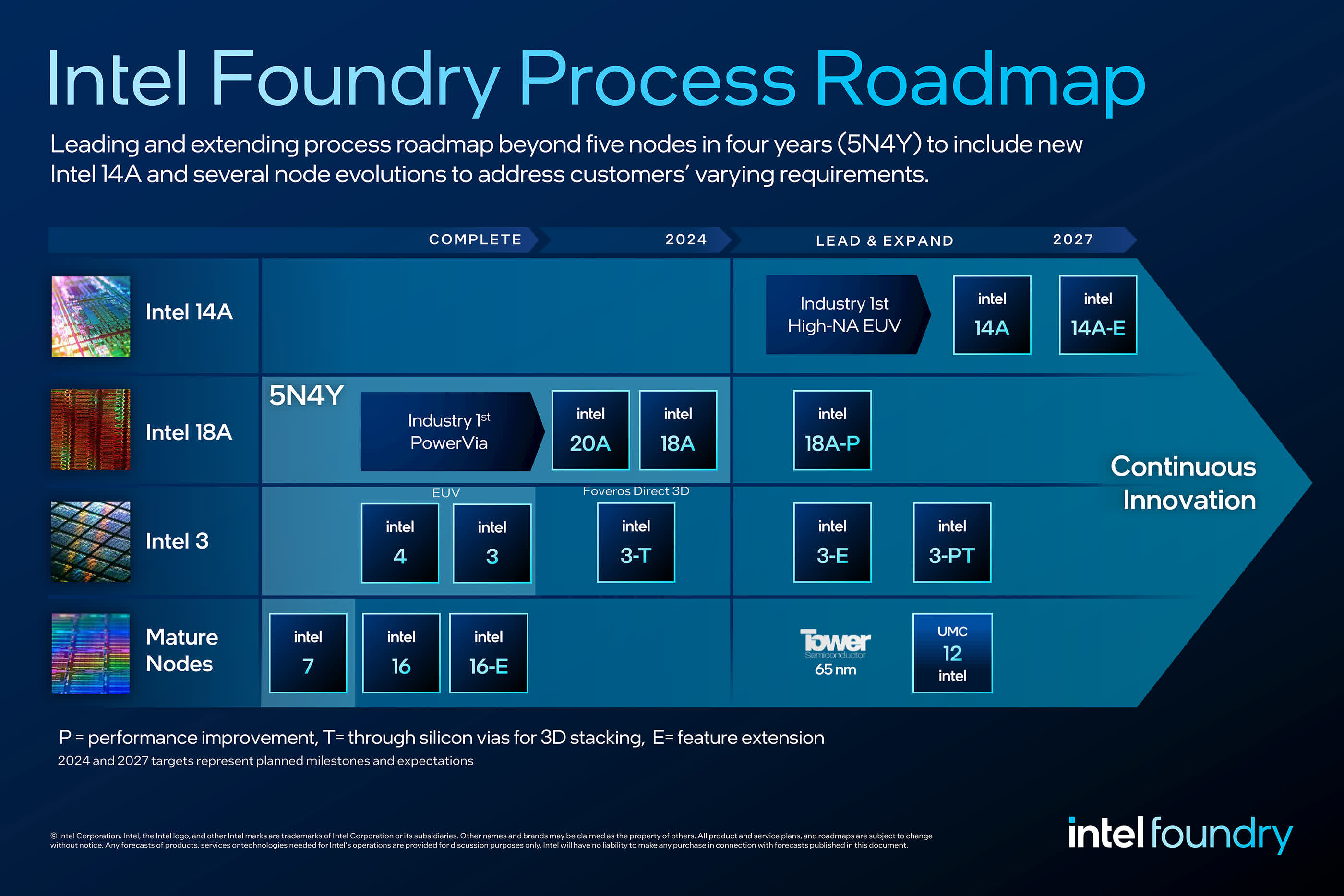

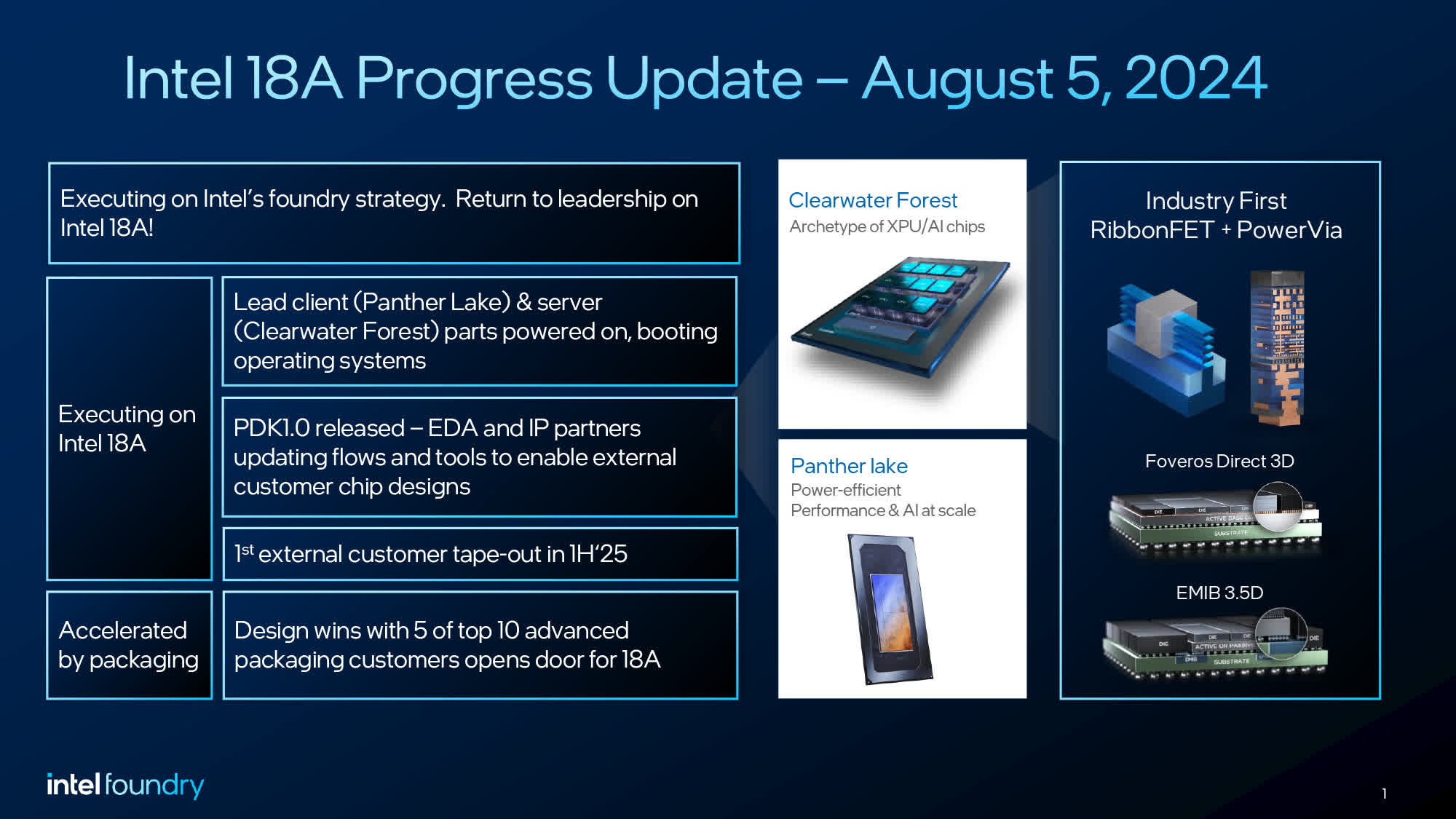

Why it matters: Intel’s future depends on the success of its 18A node, so news that the first high-volume 18A production chips are underway is a milestone for the beleaguered company. Clearwater Forest will not only establish Intel Foundry as a viable contract chipmaker, but also help it leapfrog TSMC’s 3nm technology. It also indicates Team Blue may deliver on its five nodes in four years strategy.

This week, tech enthusiasts got a glimpse of the first high-volume production chips that will be based on the Intel 18A node at the company’s Enterprise Tech Tour event in Portland, Oregon. Codenamed Clearwater Forest, this processor family represents a pivotal moment for Intel’s turnaround strategy. Its success will demonstrate Team Blue’s ability to execute its ambitious five nodes in four years strategy and, more importantly, establish Intel Foundry’s credentials as a viable contract chipmaker.

In August, Intel announced that Clearwater Forest was out of the fab and had powered-on and booted operating systems without additional configurations or modifications. While the exact release date is not specified, it is expected to hit the market sometime in 2025. The chip is designed to cater to cloud-native computing and high-density data center applications.

Intel aims to regain its competitive edge against rivals like AMD and TSMC with Clearwater Forest. While its latest Xeon 6 Granite Rapids chips – which were also displayed at the event – have matched AMD’s core counts, they still lag behind in process node advancement. Clearwater Forest is positioned to potentially leapfrog TSMC’s 3nm technology used in AMD’s upcoming EPYC Turin processors.

Clearwater Forest is based on a heterogeneous design consisting of 17 chiplets, with the compute dies at the heart of the architecture.

CEO Pat Gelsinger has been clear that the company’s success is riding on the timely development of 18A. So far, he is hitting the necessary benchmarks ahead of competing processes from TSMC and Samsung Foundry. “I think I’m a little bit ahead of N2, TSMC’s next process technology in time,” he told Barron’s late last year.

In July, Intel released the 18A Process Design Kit 1.0 for foundry customers. The process node incorporates several innovations, including RibbonFET, a next-generation transistor architecture that wraps the gate around silicon channel ribbons and promises substantial improvements in energy efficiency, as well as PowerVia. This advanced power delivery technology utilizes backside power and is expected to yield approximately 6% performance improvements. Rounding out these advancements is Intel Foundry FCBGA 2D+, a high-performance, multi-die packaging solution.

“I think everybody’s looking at the transistor of TSMC’s N2 versus our 18A,” Gelsinger said. “It’s not clear that one is dramatically better than the other. We’ll see who’s best.”

“But the backside power delivery, everybody says Intel, score. You are years ahead of the competition. That’s powerful. That’s meaningful. It gives better area efficiency for silicon, which means lower cost. It gives better power delivery, which means higher performance.”